newcustomer

Founded in 1967, Hagataya was created in order to produce cutting dies which precisely and beautifully cut through materials such as paper, textile fibre, leather, rubber, plastic film and plastic moulders.

With its sharpness, durability and fast production time, our cutting dies when used once, you can never forget. From small businesses to top listed companies we work with more than 1000 companies nationwide.

Not only do HSCD cut through flat planes, our company is the only one in the world with a hand crafted “Integrated 3D HSCD”. This machine is able to cut though CFRP moulds using HSCD specific for CFRP boards (carbon). By using the HSCD for Super Fibres we are able to cut other fibre fabrics known as super fibres (Kevlar, Dyneema, Zylon, Vectran, Twaron, Technora and Aramid) which are difficult to cut through. We have also invented the HSCD for envelopes which can cut piles of hundreds of pieces of paper at once.

What HSCD has cut through so far

・Bumpers, instrument panels, door trims, plastic moulds for automotive parts (pieces), plastic film moulds

・Holes for optional parts of automotives (fog lamp, headlamp cleaner, aero parts, camera, sensor)

* This can be done after painting whitening and burr removal.

Parts of plastic which have been deburred and drilled through, as well as processed plastic. (Materials with a layer of fibre is also OK)

PP, PE, PET, Elastics, Elastomer, ABS, Polycarbonate and felts etc. We have not only made a significant contribution to the automotive industry, but we have also contributed to the electronics and industrial goods using HSCD.

However, the issue is not cutting through one type of material, but composite materials. In recent years, we have been researching to develop a strong, but light weight cutting die. As there are a variety of composite materials, it is difficult to identify if it is easy to cut just by its appearance. At Hagataya we have been able to cut all the requested composite materials so far.

If you have materials that have not been cut through before, please bring it in and we will happily test to see if we are able to cut through the requested material. If we are unable to do so, we will make sure to develop a cutting die which is able to on your request.

At Hagataya, we strive to create high quality, world classed products by continuously challenging ourselves.

Customers who have not been happy with other companies’ always end up using HSCD because of its high quality. At Hagataya, we greatly value our customer’s comments as it helps future generations of cutter making, so please do not hesitate to let us know your opinions and impressions of our products.

Since Hagataya’s establishment, our unchanged policy is to challenge ourselves to be able to meet the customers’ needs and satisfaction.

We would like to continue to use old yet good techniques to bring you new innovative products.

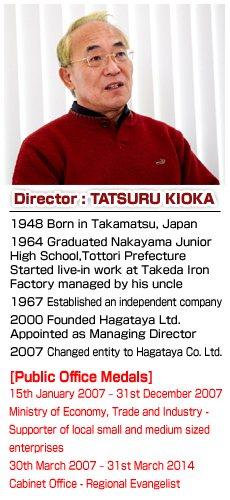

CEO Tatsuru Kioka