HSCD for CFRP (Carbon)

The only downfall of moulding Carbon Fibre Reinforced Plastic (CFRP) is the “speed of processing”.

When a HSCD is used, CFRP board (carbon) can be cut through within a matter of seconds and processing, including post processing only takes a few minutes. Please note there will be slight differences in time taken depending on the item. We are also able to manufacture with 3D HSCD which gives an exceptionally wide range of uses.

The central wooden section of the dashboard of the current Mercedes Benz S Class (Mercedes-Benz W221) (the sides have been slightly packed in) made with CFRP board (1.5mm thick carbon) using a HSCD and the HSCD used. (left)

Door handle ornament made from CFRP board (1.5mm thick carbon) cut a with HSCD and the HSCD used (right)

For example, in an automotive vehicle, depending on the model or option available, there are vehicles which have or do not have certain holes. Therefore, 2 different molding dies would be needed. When using HSCD only one molding die (a type without holes) is needed. For a type without holes, a HSCD is set and cut with a regular press machine (one or two air cylinders or motors). Not only can this be done with 2D but it is also possible to create 3D HSCD before or after painting with minimal burring which means the product can used straight away. Because heat and water is not used it is very environmentally friendly and you will be able to drastically reduce capital and running costs.

Not only do we cut automotive parts but we also cut household appliances, homemakers and industrial goods into any shape. We are the only company which manufactures 3D HSCD. Our products also have a great track record for high durability.

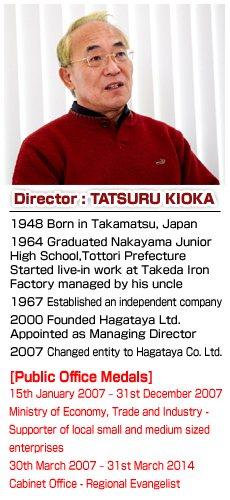

One of the great qualities of using a HSCD is that once the blade can’t cut, all you have to do is re-grind to return the blade to its original sharpness. No matter where you look, Hagataya is the only place in the world which does this. We will support you to create new high quality, world class products using Hagataya’s technology.